From Bored to Driven: Demystifying Pile Foundations Choices

Today we're going to dive deep into the most popular pile types. From driven piles and screw piles to bored piles and even micropiles. We’re going to investigate the pros and cons of each type of pile, learn the installation process and how to decide what pile foundation to use in your project.

11/26/20238 min read

Today we're going to dive deep into the most popular pile types. From driven piles and screw piles to bored piles and even micropiles. We’re going to investigate the pros and cons of each type of pile, learn the installation process and how to decide what pile foundation to use in your project.

But before we embark on this journey, let’s establish a fundamental understanding of what a pile foundation is.

What is a Pile Foundation?

At its core, a pile foundation is a specialized form of deep foundation designed to support structures by transferring loads from the structure to a deeper level within the Earth. It consists of long, slender columns or piles, typically made of materials like concrete, steel, or timber, that are driven or installed into the ground.

Now, let's categorize these foundations to simplify our understanding. Pile foundations can be broadly classified into two main categories: displacement and non-displacement piles.

Non-displacement piles involve drilling a hole, extracting soil, and replacing it with concrete. Conversely, displacement piles push through the soil, displacing it laterally and compacting the surrounding area.

Categories and Sub-Categories of Pile Foundations

To further refine our understanding, let's explore the three sub-categories based on their load-bearing mechanisms: Base bearing, shaft friction, and a combination of both.

Base Bearing Piles: These piles derive their strength primarily from the bottom part of the pile, resting on rock, hard, or dense soil.

Shaft Friction Piles: Strength for these piles comes from the sides of the pile rubbing against the surrounding soil.

Combination of both: As the name suggests, these piles harness strength from both side friction and base bearing.

Deciding on Pile Foundations: A Strategic Approach

Now that you know what a pile foundation is, let’s navigate the decision-making process. When do we choose pile foundations over other options?

Soil Bearing Capacity:

The fundamental factor lies in soil bearing capacity. Footings must be founded on material meeting the minimum bearing capacity nominated by the engineer. For instance, residential projects often demand a minimum of 100kPa bearing capacity. If the geotechnical report indicates a weak topsoil layer with less than 100kPa, it's time to contemplate piles.

Take, for instance, a house we designed on the Gold Coast, featuring a 1.5m layer of uncontrolled fill underlain by a meter of loose sand and soft silty clay, necessitating 3m deep screw piles.

Photo credit to: www.realestate.com.au

Check out my Instagram page to see photos of the building in construction: Gabriel Ribeiro (@beng_gabriel) | Instagram profile

Snip of the Soil Report

Lateral and Uplift Forces for Light Structures:

Piles shine in scenarios where structures face significant lateral and uplift forces. This applies to tall buildings, free roofs, carports, sheds, transmission towers, and retaining walls. Piles are an efficient way to ensure the stability of the system due to their friction capacity.

While the self-weight of shallow footings might resist the uplift forces and overturning, the costs and size of footings (pad footings for instance) in light structures could outweigh the costs of piles.

Preventing Overload on Existing Structures:

Piles play a pivotal role in preventing overload on existing structures by alleviating pressure exerted by shallow footings. When a new structure is introduced, its footings can create additional loads that might adversely affect neighboring structures or utilities.

Consider examples like the footings of a high-rise building surcharging basement walls next door or a pad footing impacting an existing retaining wall. The footings of a house will surcharge the walls of an existing pool previously installed on the site. The footings of a building will surcharge the council stormwater and sewer pipes running across the property.

Proximity to Water Table:

In cases where the water table is close to the ground surface, constructing shallow footings becomes intricate. Piling circumvents the challenges of constant de-watering, ensuring a stable construction environment.

Piles, with their end-bearing capabilities, efficiently transmit loads to the foundation, preventing additional stress on existing structures.

Footings on Slopes:

When dealing with footings on slopes, the lack of soil on the slope side can compromise stability with shallow footings. While not dismissing the use of shallow footings entirely, contemplating a pile foundation becomes a prudent consideration. This is especially true when factoring in potential issues like landslides and unstable foundation conditions, linking back to our initial emphasis on bearing capacity and soil conditions.

Illustration credits to: Australian Geomechanics Society

There is a case though that you must be very careful when using piles, because if you don’t, the consequences could be devastating and I will disclose that information after we go over the most common pile foundation types. 😮

Let's proceed to understand how those piles are constructed and the pros and cons of each one of them.

Pile Foundations: Construction Methodology

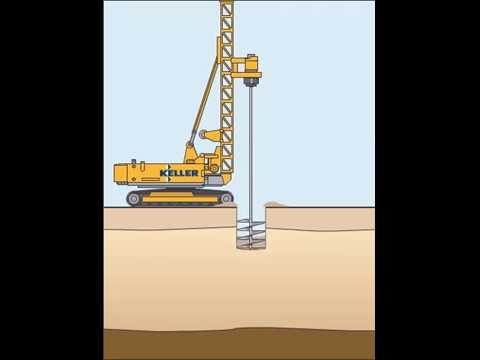

Bored Piles:

They are high-capacity drilled piers constructed by drilling a cylindrical hole of the required depth and subsequently filling it with concrete. They may or may not require a reinforcing cage and some bored piles can be constructed with an enlarged base to help with bearing and uplift.

Another type of drilled pier is the CFA Continuous Flight Auger: They are similar to bored piles. The difference is that CFA’s have cutting blades that span the entire length of its drill shaft and a hollow tube that allows for the pumping of concrete as the auger is retracted from the hole. Unlike the bored piers, the excavated soil is not removed progressively but instead remains in the hole between the cutting blades. And The reinforcement cage is inserted into the still wet concrete.

Video credits: Keller Group Youtube Channel

PROS:

They eliminate the need for pile caps.

Fewer piles (but with larger diameter shafts ranging from 300mm to 2400mm).

No vibration or noise.

Can go through boulders and be socketed into rock.

High load capacity.

Base can be enlarged for higher capacity.

Can form a composite pile with steel columns (soldier pile walls).

CONS:

Not ideal for collapsible soils (unless encased).

Not ideal in shallow water table zones (CFA may be used).

Bad weather conditions may make drilling and concreting difficult.

Disposal of soil from drilling (spoil).

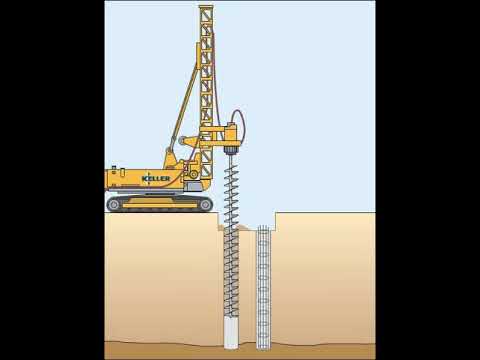

Screw Piles:

Screw piles consist of circular steel hollow sections fitted with a single or double helix at the tip. Installation involves using a hydraulic excavator to screw 4m-long sections of steel piles connected to each other, into the ground. Diameters range from 76mm to 273mm and they are widely used in the construction industry in Australia, especially in the residential market.

Video credits: Keller Group Youtube Channel

Video credits: Katana Foundations Youtube Channel

PROS:

No vibration or noise.

Speed of installation.

Low mobilization costs due to small and inexpensive equipment.

Ideal in shallow water table zones.

No spoil to be removed from site.

Weather conditions don’t affect installation.

Can be installed in confined spaces, which makes them Ideal for remedial works.

CONS:

Not suitable for rock without pre-drilling.

Difficult installation in trash fill with concrete and other building material debris.

Load bearing capacity is limited. A typical 76.1mm with 300mm Helix can take approximately 100kN in stiff soils.

Buckling limits its capacity in very soft soils.

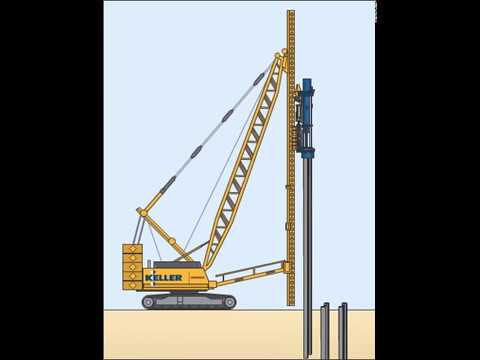

Driven Piles:

Driven piles are installed using impact or vibration hammers with a steady succession of blows on the top of the pile. They can be constructed from steel, timber and pre-cast concrete.

They are classified as displacement piles and gain substantial capacity by displacing the soil around the shaft and compacting the soil.

Video credits: Keller Group Youtube Channel

PROS:

No spoil to be removed from site.

Can be used in aggressive soil conditions.

Speed of installation.

Ideal in shallow water table zones.

CONS:

Noisy and considerable vibration may damage adjacent properties.

Typically not suitable for rock.

Timber piles may need treatment, specially if subjected to alternate wetting and drying.

And their Uplift capacity is limited if the pile cannot be driven deep enough into the ground.

Franki Piles:

Also known as enlarged base driven cast in-situ piles and they are installed on-site using a drop weight and temporary casing.

In the Franki Pile Construction process, a dry concrete mix is compacted at the bottom of the casing using a drop hammer, creating a driving plug. The temporary casing is then driven into the ground until the desired depth. Additional dry concrete mix is added and expelled to form the enlarged base. After forming the enlarged base, reinforcing steel and high slump concrete are placed in the casing and finally the casing is removed.

Video credits: Keller Group Youtube Channel

PROS:

High bearing and uplift capacity due to the enlarged base.

Ideal in shallow water table zones due to the casing.

No spoil to be removed from site.

CONS:

Limited depth of installation

Noisy and considerable vibration

Not suitable for rock

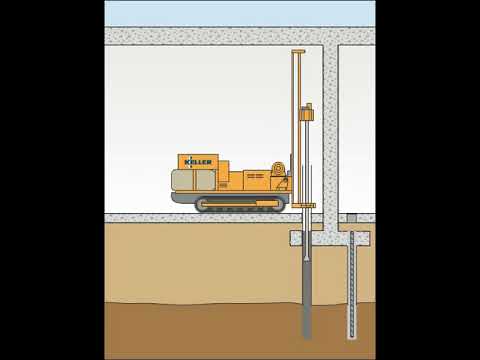

MicroPiles:

Micropiles are essentially mini bored piles. Their diameter ranges from 50 to 300mm and they are mainly used to strengthen existing footings.

Initially, a steel casing is pressed into the soil to the required depth, and a flushing method removes soil by introducing pressurized water. Concrete is then placed using the tremie method, with the steel casing simultaneously extracted. Following this, a single centralized bar is typically plunged into the still-wet concrete.

Video credits: Keller Group Youtube Channel

PROS:

Can be installed in confined spaces, which makes them Ideal for remedial works.

Minimal spoil to be removed from site.

Minimal noise and vibration.

CONS:

Not suitable for large loads

I remember back when I lived in Brazil, there was a Social housing program called "My House, My Life" and hundreds of brick houses had been built on a low bearing capacity soil. Not long after the project had been completed, the walls started cracking due to differential settlement. Micropiles were used to save the project.

Navigating Hazardous Terrain:

There is a special case where you should be very careful when using piles. Imagine this: your construction site is sitting on top of closed landfill or hazardous waste sites. Now, that's a whole new level of tricky. Drilling into that ground? Risky business. You could stir up dangerous stuff, like gases that can be dangerous if inhaled or even worse, the possibility of an explosion.

Hope you enjoyed this blog post. Stay tuned for more and don't forget to subscribe to my newsletter and Youtube Channel.

Cheers